Features and Benefits

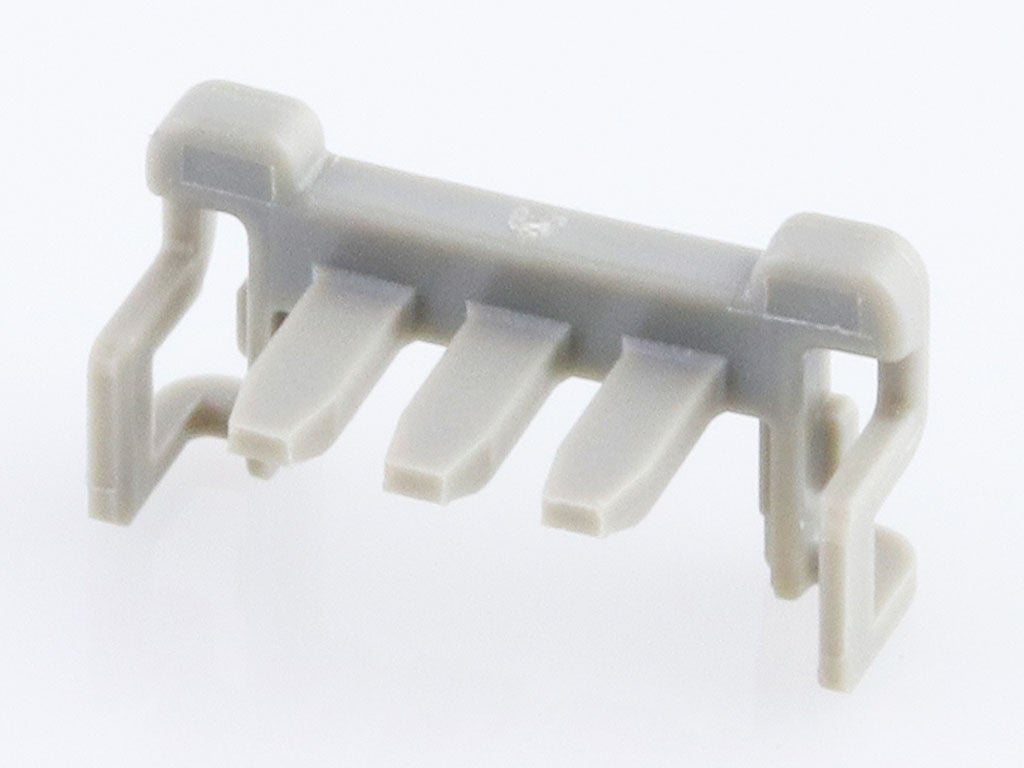

In high-vibration environments such as automotive and major appliances, consistent power connectivity requires compact, robust connectors that can withstand vibration. DuraClik Connectors ensure a secure and reliable connection due to their retention force of up to 100N. The independent secondary lock (ISL) ensures terminals are fully inserted and securely locked, reducing the risk of signal loss or disconnection. The audible click upon proper mating and built-in inertia lock help reduce installation errors and enhance reliability. Because extreme thermal conditions pose significant challenges, DuraClik Connectors are engineered to withstand high temperatures by delivering robust performance even in environments that reach up to 125°C.

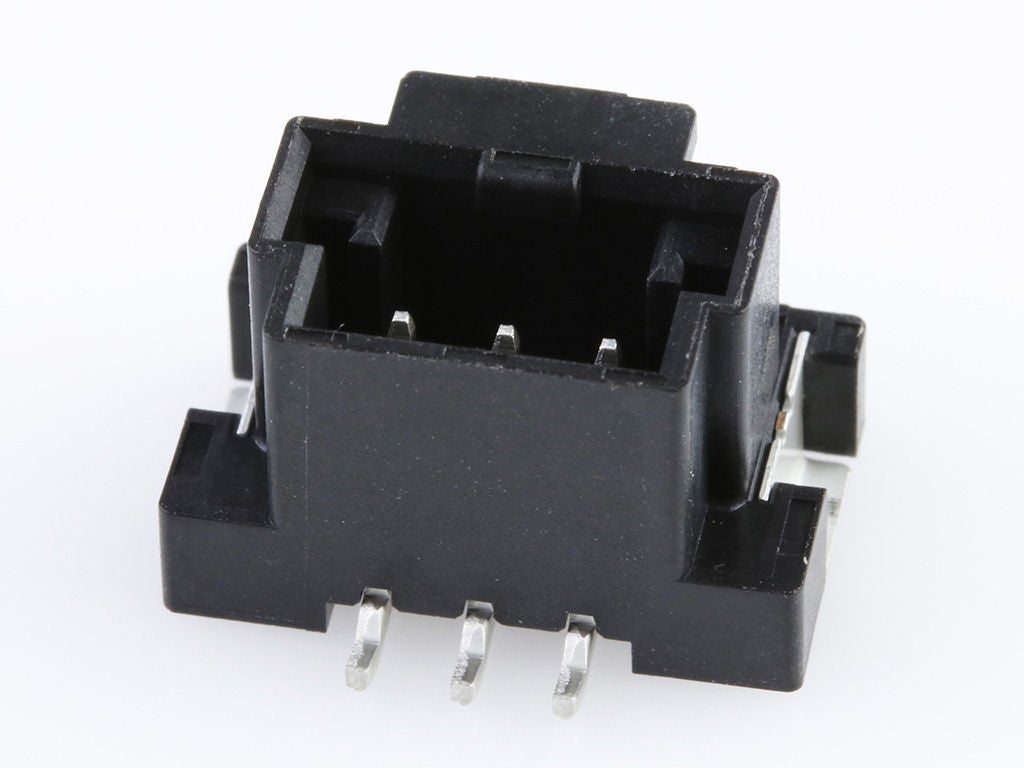

DuraClik Connectors are available with two to 24 circuits, including single- and dual-row connectors that optimize limited PCB space. Options for tin and gold plating as well as vertical and right-angle header orientations are available, including a robust version for high-vibration applications. These connectors are suitable for a wide range of applications, including automotive LED lighting and washing machines. Versatile enough to adapt to numerous design needs, DuraClik Connectors meet rigorous automotive standards, conforming to LV214 (S2 vibration), ES91500-03 and SAE/USCAR-21 specifications.

| DuraClik Feature | DuraClik Standard | DuraClik TPA | DuraClik ISL | DuraClik Robust Dual-Row |

|---|---|---|---|---|

| Receptacle Size (Depth) | 6.50mm | 7.45mm | 8.50mm | 17.70mm |

| Current | Up to 3.0A | Up to 3.3A | ||

| Temperature Rating | -40 to +105°C | -40 to +125°C | -40 to +130°C | -40 to +125°C |

| Receptacle Termination | Crimp | |||

| Rention Force | 9.8N | 20N | 50N | 100N |

| Retainer | - | Y | Y | Y |

| Available Circuit Sizes | 2 to 15 | 2 to 10, 12, 13, 15 | 16, 24 | |

| Plating | Tin, gold | Tin | ||

| Header Size (Depth) | 8.00mm (vertical), 9.40mm (right angle) | 18.30mm | ||

| Header Termination | Surface-mount technology (SMT) | |||

| Available Header Circuit Sizes | 2 to 15 | 16, 24 | ||

| Header Temperature Rating | -40 to +130°C | -40 to +125°C | ||

Featured Videos

Applications by Industry

Air-Conditioning

Center Stack System

Cranes

Domain Control Unit

Electric Vehicles

Exterior and interior lighting

Heads-Up Display

Instrument Cluster

Inverter

Shift levers and steering components

Tractors

Trucks

Wiper and blinker levers

Zonal Architecture

Zonal Control Unit

Factory automation

Industrial machinery

This is not a definitive list of applications for this product. It represents some of the more common uses.

Frequently Asked Questions

What are DuraClik Connectors?

DuraClik Connectors are 2.00mm-pitch wire-to-board power and signal connectors that deliver secure, reliable connectivity in high-vibration environments, such as automotive and heavy-appliance applications. These compact connectors offer different versions to meet application-specific needs for retention force, circuit count, temperature rating and current.

What are the differences between different versions of DuraClik Connectors?

There are four DuraClik versions: Standard, TPA, ISL and Robust. Features such as retention force, temperature range and current capacity vary between versions. DuraClik Robust connectors offer a retention force of 100N (10.2kgf), temperature range up to +125°C and up to 3.3A of current capacity.

What makes DuraClik Connectors suitable for high-vibration environments?

DuraClik Connectors are designed with up to 100N retention force to ensure secure and reliable connections even in high-vibration conditions. Additionally, features like the independent secondary lock (ISL) and the audible “click” upon proper mating further enhance stability and prevent accidental disconnections, making them ideal for demanding automotive and industrial applications.

What temperature ranges can DuraClik Connectors operate in?

DuraClik Connectors are capable of operating in a wide temperature range from -40°C to 125°C. This high-temperature tolerance makes them suitable for environments requiring robust thermal stability, such as automotive lighting and consumer white goods.

Are DuraClik Connectors compliant with automotive industry standards?

Yes, DuraClik Connectors meet stringent automotive industry standards, including LV214 (S2 vibration), ES91500-03 and SAE/USCAR-21. This compliance ensures that the connectors are suitable for high-performance and high-reliability automotive applications.

How do DuraClik Connectors optimize space in PCB design?

The DuraClik 2.00mm-pitch wire-to-board connector system features a compact design that helps save space on the PCB. Available in various configurations, including vertical and right-angle headers, these connectors allow for efficient use of PCB real estate, which is crucial for modern automotive and industrial electronics designs.

?ts=1770678430229&dpr=off&wid=320)