The Transformation of Surgical Robot Design

As the field of surgical robotics advances, integrating AI and ML becomes critical to deliver new capabilities like real-time decision making, predictive analytics and autonomous navigation. At the same time, developments in haptic feedback are creating more intuitive interfaces for surgeons, providing a more realistic control of remote instruments. Demand is also growing to build smaller and more portable units that enable the ability to perform surgeries in underserved areas.

In response to these trends, design engineers are tasked with integrating machine automation and user-centered controls into existing surgical workflows, while maintaining compatibility and space efficiency across a diverse range of medical devices.

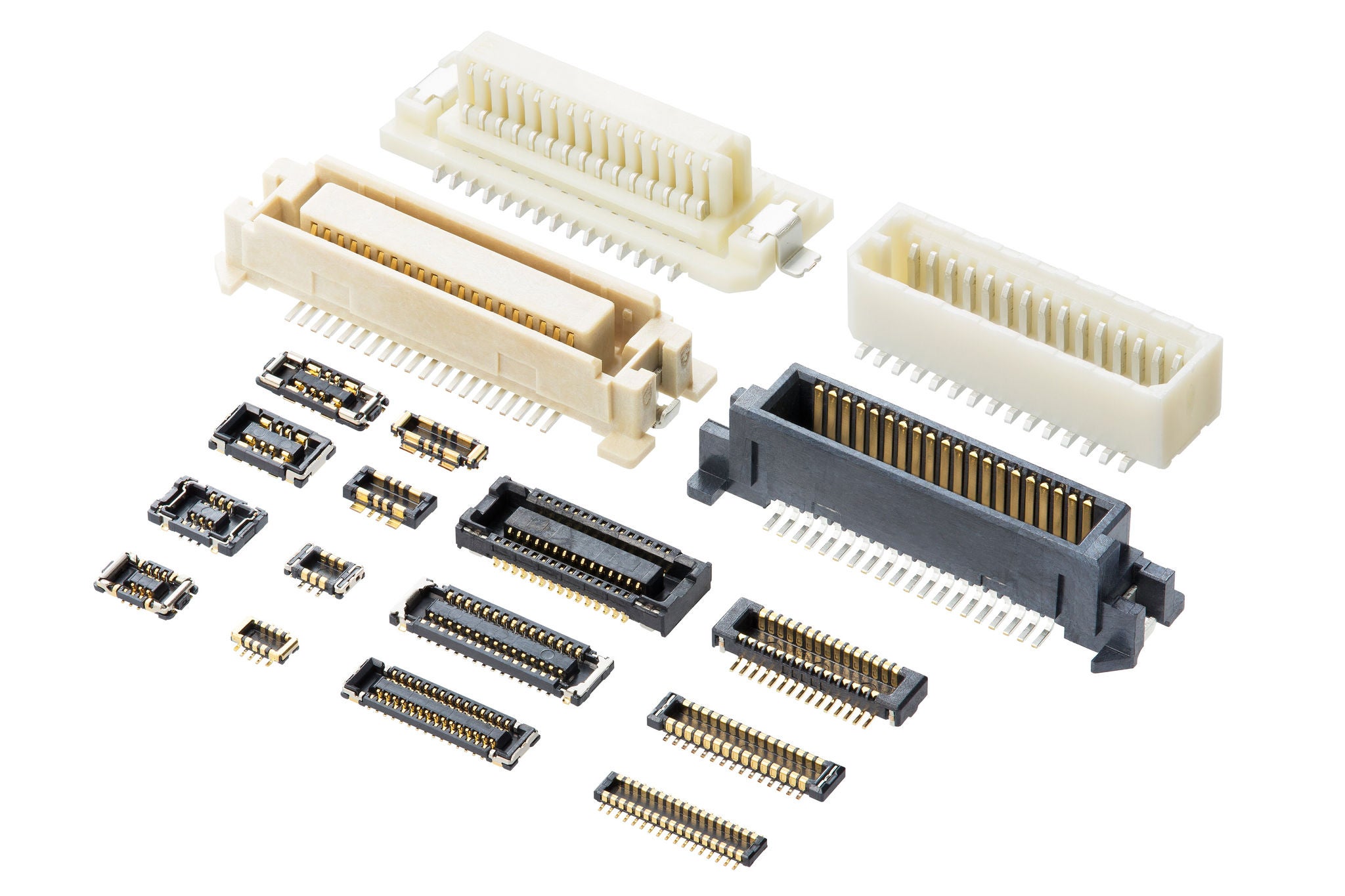

Molex sets the standard in the industry with dependable, high-speed connectors and cables ideal for precision robotic surgery. Our robust, miniaturized components aid in the design of minimally invasive procedures that reduce recovery time, lessen pain and lower the risk of infection. The surgical units that feature these components also offer greater portability. With a comprehensive portfolio, Molex provides a variety of proven connectivity solutions that ensures seamless, system-wide interoperability.