Features and Benefits

Operators often face challenges ensuring connectors are accurately and securely mated, especially during blind-mating operations. Assembly process delays and errors occur due to high insertion forces and unconfirmed connector mating. To help prevent costly rework or connection failures, there is a significant need to ensure secure and reliable mating while reding assembly time.

Robust connections require dependable locking mechanisms that secure connectors once mated. An audible click provides clear confirmation that the connector is properly engaged, even when not visible. Additionally, low insertion force connectors help avoid delays and minimize errors, saving time for operators.

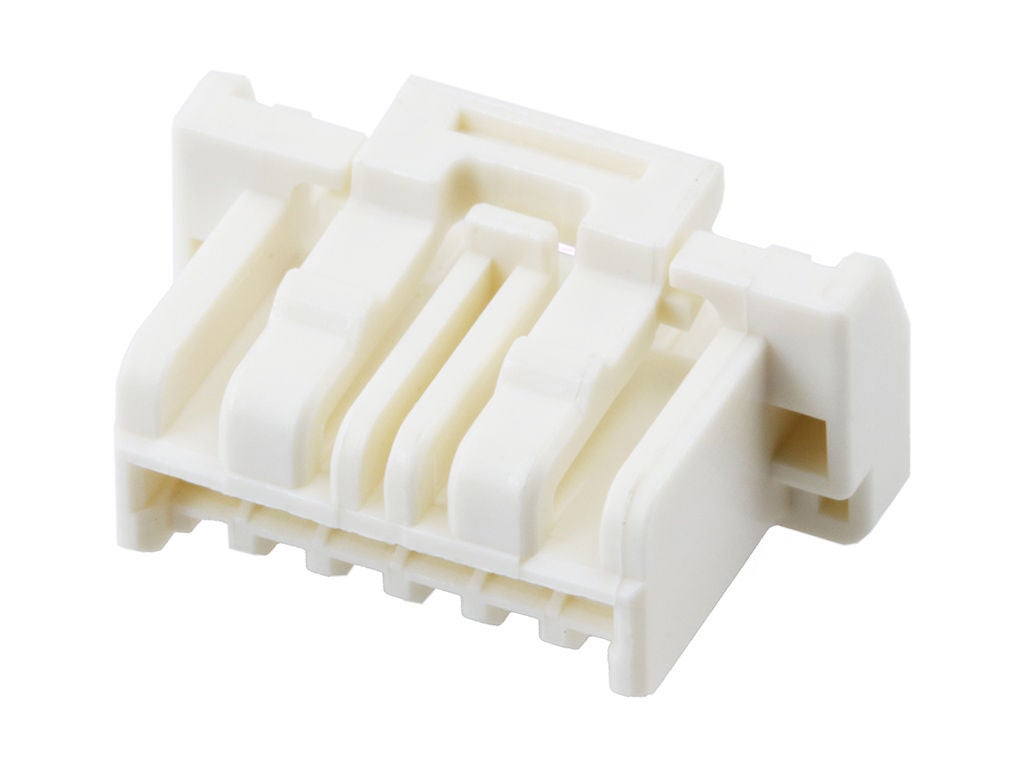

Molex CLIK-Mate Connectors feature a low insertion force and integrated locking mechanism, reducing operator physical strain, assembly time and the risk of connector damage. Audible click feedback confirms successful mating without visual verification, mitigating connection errors. The secure CLIK-Mate connector design enhances the durability and reliability of the assembled product, making the mating process easier and faster for operators.

Applications by Industry

Drones

EVTOL aircraft

Blenders

Coffee makers

Printer and copy machines

Refrigerators

Sewing machines

Vacuum cleaners

2-Wheelers, 3-wheelers and e-bikes

Control modules

Electrification: OBC, DCDC, PDU, BMS equipment

In-cabin applications

Lighting and lamps

Steering control systems and sensors

Telematics

Zonal architecture

Charging stations

Air-conditioner units

Industrial robotics

Inverters

Machine builders

Power-distribution systems

Servers

Switches

Cooling- and thermal-management systems

Open compute project

Servers and switches

This is not a definitive list of applications for this product. It represents some of the more common uses.

Frequently Asked Questions

What are CLIK-Mate Connectors?

CLIK-Mate Connectors are advanced wire-to-board connectors designed for applications that require durable and reliable connections while maintaining a compact form factor. These connectors feature an audible click for secure mating.

What makes CLIK-Mate Connectors reliable and secure?

CLIK-Mate Connectors feature an inner positive lock that provides a secure, vibration-resistant connection. Combined with a unique tuning-fork terminal design, these connectors ensure robust electrical contact with a low insertion force and long-term reliability.

Are CLIK-Mate products certified to automotive standards?

CLIK-Mate 1.50mm-pitch connectors are USCAR2 V2 certified for vibration and mechanical shock and have excellent performance in harsh automotive environments.

What pitch sizes are available for CLIK-Mate Connectors?

CLIK-Mate Connectors are offered in multiple pitch sizes: 1.25, 1.50 and 2.00mm.

What plating and material options are available?

CLIK-Mate terminals are commonly tin plated for cost savings, with optional gold-plating variants to further extend durability. Gold-plating variants have three plating thickness: 0.10, 0.38 and 0.76µm for the 1.50mm-pitch connector. The housing uses flame-retardant materials with UL94 V-0 rated.

Are CLIK-Mate Connectors easy to assemble?

Yes, they feature low insertion force terminals and a positive lock for easy assembly with an audible click, which makes it easy for the operator to confirm proper mating.