Back to Industries & Applications

Rugged, Reliable and Miniaturized Connectors for Critical Aerospace Applications

The aerospace industry is propelling the evolution of more sustainable, all-electric aircraft, embedding innovative digital tools to optimize efficiency and reduce emissions. From autonomous drones to IoT-enabled, real-time analytics, these advancements are reshaping aviation to meet modern customer needs and stringent safety standards.

Compliance with these strict aerospace mandates requires robust design and rigorous testing. Connectors and components must adhere to AS9100, MIL-SPEC and DO-160 standards to ensure safety and reliability in extreme environments, while the increasing threat of cyberattacks demands secure, EMI/RFI-shielded connectivity solutions to protect critical avionics and communications.

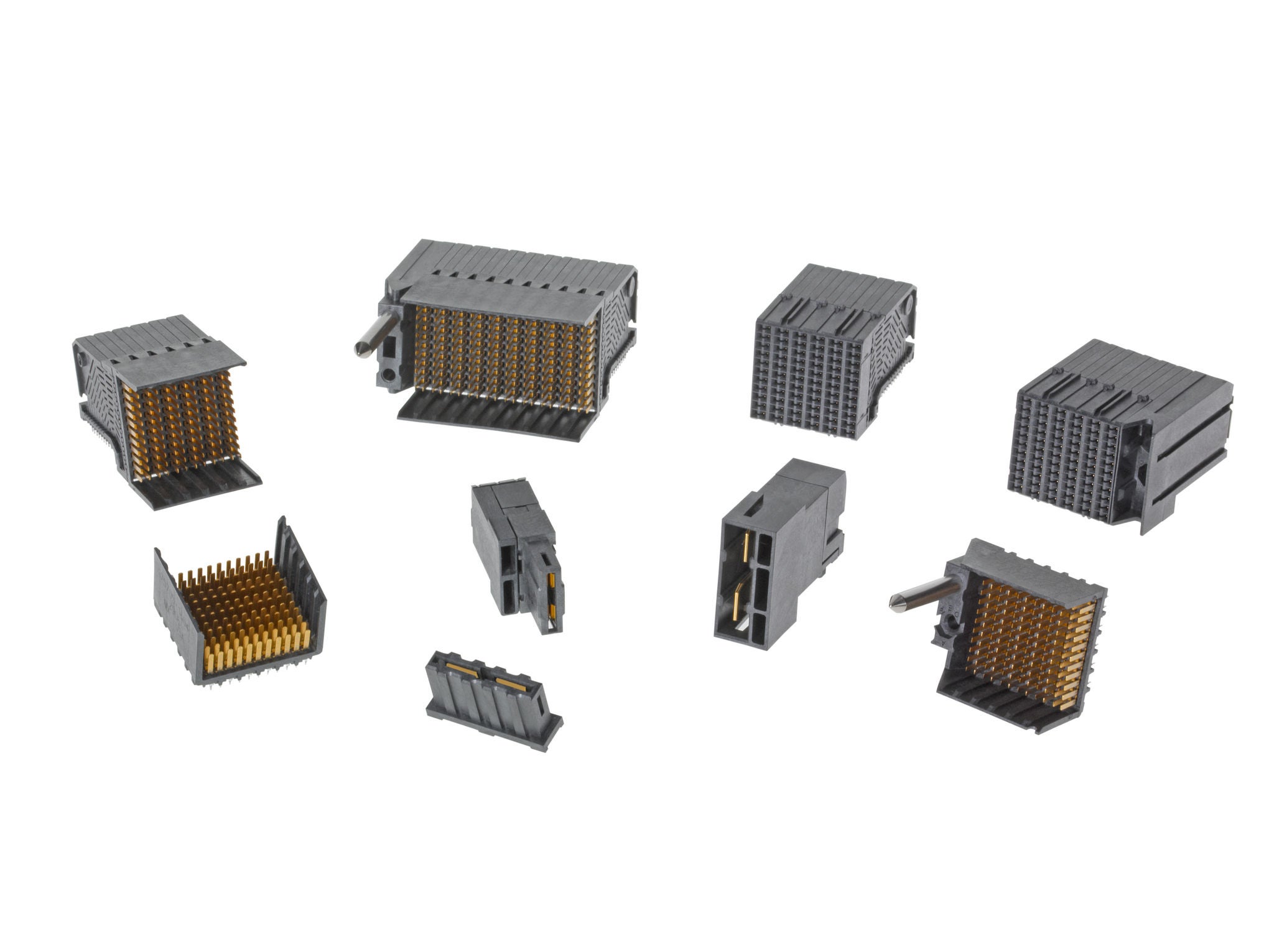

The combined power of Molex and AirBorn, a Molex company, supports aerospace system architects by providing cutting-edge connectivity solutions that meet or exceed regulatory standards. Our expertise spans high-power, EMI/RFI-shielded products and tailored solutions, allowing customers to tackle complex design challenges, enhance safety and gain a competitive edge through our innovation-focused ecosystem and commitment to quality.